Intelligent and Automated Quality Inspection

The quality of your products always in perspective

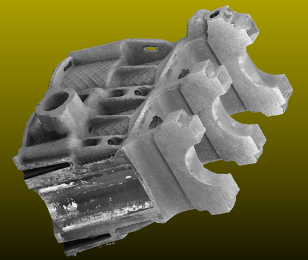

Unclean weld seams, powder burns, burns or scratches: it is not uncommon for industrially manufactured workpieces to have unwanted remnants from their production.

Having these inspected and sorted out by specialist staff is not only a time-consuming, expensive process – it is also prone to errors. A purely visual inspection misses up to 30% of all defects. With LumiScan QI and its integrated Machine Learning, you can automate this process reliably and cost-effectively.

From image recording to IO/NIO decision

Machine Learning and Deep Learning for best results

Fast customisation thanks to standard components and individual setup

%

Reliability of decisions

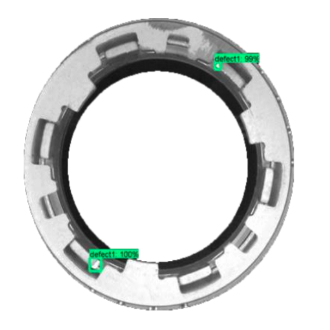

Marking of defective areas with bounding boxes

Detect any defect with the power of AI

LumiScan QI reliably detects faults and defects in shape, colour and surface on workpieces after a short training period.

Thanks to integrated Machine Learning and Deep Learning, extensions and subsequent training are no problem.

Best results through intensive training

As in football, the coach does not send their best player out onto the field without training. The same applies to neural networks: for a successful end-of-line control you need on average up to 50 samples.

This means you are always on the safe side.

Highest precision

It’ s quite clear: expensive mistakes have to be avoided. To ensure that this always succeeds, LumiScan QI can detect defects to within 0.1 mm.

Special solutions are possible for even smaller defects. Thus, unwanted deviations are a thing of the past.

Individual setup

Every workpiece is different. LumiScan QI takes this fact into account with standardised modules that are individually assembled and adapted for each inspection task.

Regardless of whether it’s a bread roll, a piston or the rear of a car: in the blink of an eye, you get a consistent system that is perfectly adapted to your needs.

More info on quality inspection

Please get in contact with us for additional information. We will get back to you as soon as possible.