Why actually light field? In contrast to conventional methods of image acquisition, the light field offers a whole range of special properties and advantages. They can make machine vision of complex objects much easier – and thus more economical. In this article, we would like to show why the light field represents a unique opportunity for machine vision and how companies can exploit these opportunities for themselves.

The light field comprises the totality of all light information in a scene. This approach thus brings with it a whole range of properties that can be used to advantage in machine vision. In particular, the light field succeeds by reducing system complexity and enabling fast acquisition. The light field technology completely dispenses with long exposures, camera movements or similar.

Generating more and more reliable image information

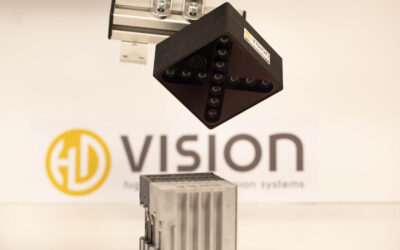

First of all, more information leads to better results. This is also confirmed when using the light field. Typically, light field cameras are used as camera or lens arrays, which leads to significantly more image information. The LumiScanX sensor, for example, has 13 cameras that all capture an image scene from slightly different positions. An associated software simply calculates out offsets, ambiguous areas and more afterwards.

This effect is particularly noticeable when capturing metallic and shiny surfaces or fiber composites. Conventional methods quickly reach their limits here without a sample projector. A light-field camera, on the other hand, can extract the resulting light reflections from the individual images by means of their different angles of incidence. The surface of the recorded point cloud is densely filled.

The situation is similar with the edges and sides of captured objects. Again, the light field approach helps to capture more image information. Less occlusions and a more complete 3D image are the result. More precise point clouds consequently lead to more powerful machine vision. 3D reconstruction, image segmentation, but also object recognition benefit from light field technology.

Handling image sharpness – a special feature of the light field

Another bundle of features of the light field concerns image sharpness: the depth of field of a captured scene decreases almost linearly as the distance increases. Other methods have to contend with exponential inaccuracy here. However, deep boxes or high industrial ceilings are by no means a knockout criterion for light field sensors.

In general, the sharpness of light field images behaves differently than usual. The image acquisition in the array delivers a large number of individual images – all with a slightly shifted focus point. The associated software uses this information to remove any image blur. What remains is a scene that has been captured in sharp focus everywhere. In film production, editors use this to subsequently focus on the right areas. In industry, the light field provides an all-around precise scene to generate exact point clouds.

Incidentally, the film industry is not the only area besides industrial manufacturing where light field technology is used. For generating 3D shots, augmented or virtual reality, the light field can generate complete scenes in no time.

On the way to becoming the new standard?

This is another reason why the technology is already well on its way to becoming the new industry standard there. In the manufacturing industry, the light field has so far been used primarily in the microscopic area. However, the technology is increasingly being used for larger objects as well, especially in quality inspection or in the automated handling of parts. In the next few years, the light field could also become the new standard here.