Precise and Safe: How Noise Reduction is Revolutionizing Robotics

Imagine navigating under a clear night sky with the stars as your reliable guides. But what if some of those stars, like Polaris — the North Star, were slightly out of place? Even the smallest deviations could cause you to lose your way and miss your destination.

The Challenge of Noise in Point Clouds

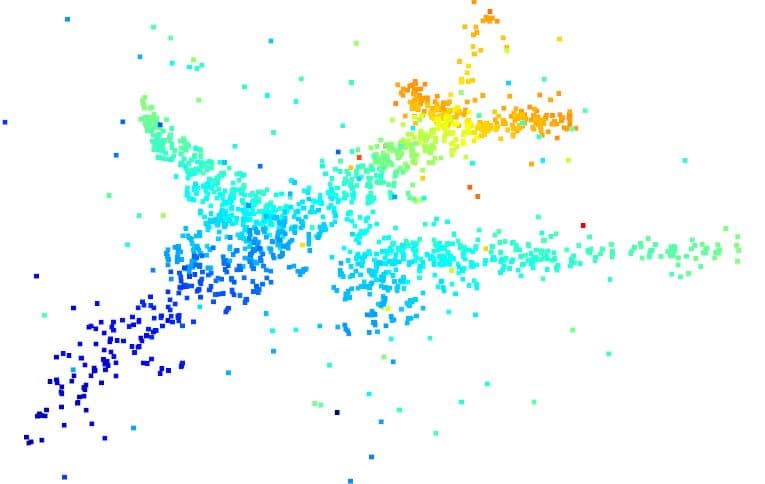

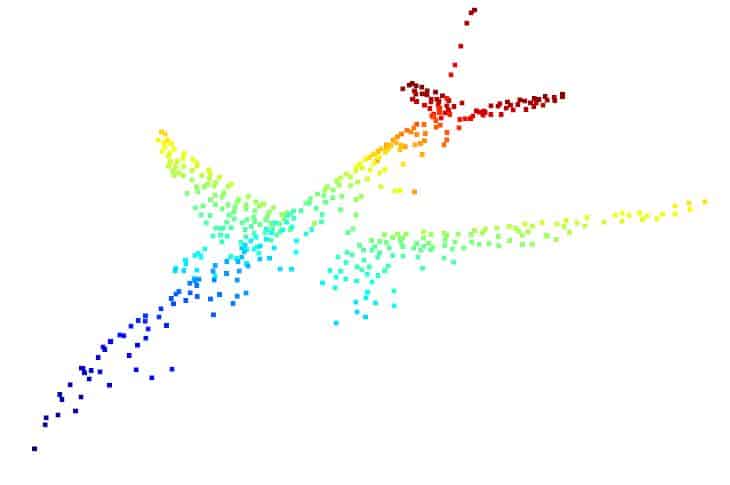

The same concept applies to point clouds in modern technologies. These three-dimensional data points describe objects through points on their surface. An illustrative example is the point cloud in the illustration, representing the top half of an airplane with and without noise. Such point clouds, which capture the environment, are like stars that help robots understand their surroundings and navigate safely. But what happens if some of these points are “noisy” and therefore displaced? An autonomous vehicle might miss an obstacle, or a robot might fail to pick up a component correctly — all because the underlying data is inaccurate.

Our LumiScanX camera systems capture the environment in the form of point clouds, providing robots with the foundation to understand and interact with their surroundings. Whether in the automation of manufacturing processes or other complex industrial tasks like the quality inspection of components, the precision of our systems is already in the millimeter range, making them highly accurate. However, we see potential for further improvement: Achieving even greater accuracy can not only refine results but also open up new applications.

PointCloud Airplane Noisy

PointCloud Airplane Clean

Optimizing Precision through Machine Learning

In recent years, the rise of machine learning has enabled significant advances in the denoising of point clouds. Our research shows that many of these new approaches deliver impressive results, especially when processing complex data. In tests, the accuracy of our systems could already be increased from 0.77 mm to 0.40 mm. However, our team, led by our denoising expert Maximilian Michael Winterer, has identified that many of these denoising techniques can be further optimized, as they are not specifically tailored to the requirements of real-world applications in robotics.

Under the leadership of Mr. Winterer, we are developing a new denoising algorithm specifically designed for the structure of our robotics data. By adapting it to our specific application requirements, we aim to create a denoising method that surpasses the currently available approaches in robotic applications. This additional accuracy is crucial to unlocking the full potential of our technologies, exploring new areas of application, and further strengthening confidence in the use of robotic solutions.

Fractal Analysis: An Innovative Evaluation Method

In his research, Mr. Winterer also discovered that the current methods for evaluating denoising algorithms are incomplete. There is a lack of a method that allows statistically significant statements about whether small but essential details are excessively smoothed along with the noise or whether they are preserved — similar to editing a digital photo, where smoothing noise should not cause fine textures and details, like the leaves of a tree, to disappear.

To address this gap, the team around Mr. Winterer developed a new metric based on the principles of fractal analysis. Fractals, such as those found in nature in ferns or seashells, are characterized by repeating patterns that occur on ever-smaller scales. “We have adapted a methodology to analyze such geometries to ensure the highest quality in denoising our point clouds. With our new metric, we can ensure that denoising methods preserve the finest details. This is crucial for further enhancing the precision and reliability of our systems,” explains Mr. Winterer.

A Glimpse into the Future: Highest Precision and Safety for Our Customers

We are in the process of further developing our denoising in order to provide our customers with even greater assurance of accuracy in the future. The new in-house developed evaluation method will allow us to consistently guarantee this accuracy to our customers, which is especially important for applications with extremely high accuracy requirements. The increased accuracy will also make it possible to serve new sub-millimeter applications in robotics and automation that were previously not possible. We are also working to reduce the computational time of denoising algorithms so that they can be integrated into ever faster automation processes. In this way, we are laying the foundation for future-proof and safe robotics applications.

Finally, a question for you: What does this mean for the future of your applications? What new areas of automation can you tackle with this increased safety and precision?