Object detection is a key technology in industrial machine vision systems, used to automatically identify, locate, and classify objects within images or video feeds. It plays a critical role in enhancing productivity, ensuring quality control, and improving safety in manufacturing environments. The process involves capturing images, processing them to enhance quality, and applying algorithms to detect objects based on their distinctive features.

Modern industrial image processing systems increasingly rely on deep learning models powered by convolutional neural networks (CNNs). They offer real-time performance with high accuracy, making them well-suited for industrial applications. In quality control, object detection systems inspect products for defects such as cracks, misalignments, or surface flaws, ensuring consistency in manufacturing. Vision-guided robots use these systems for automated tasks like picking and sorting, streamlining production processes.

Efficiently Training an Object Detection Model

The advantages of object detection include increased efficiency, greater consistency, and significant cost savings due to reduced manual labour and faster processing times. However, challenges remain, including high implementation costs and the need for large datasets to train deep learning models. Environmental factors like poor lighting or partial occlusions can also affect system performance.

A key advancement in object detection has been the application of data augmentation strategies that reduce the dependency on large datasets. HD Vision Systems, under the supervision of Quirinus Schwarzenböck, developed a specialized data augmentation pipeline, tailored for industrial application. By synergizing innovative and existing augmentation methods, this pipeline effectively trains models to detect previously unseen objects. This reduces the cost and time required for manual data collection and labelling, accelerating deployment while maintaining robust and high-performing models.

Oriented Object Detection

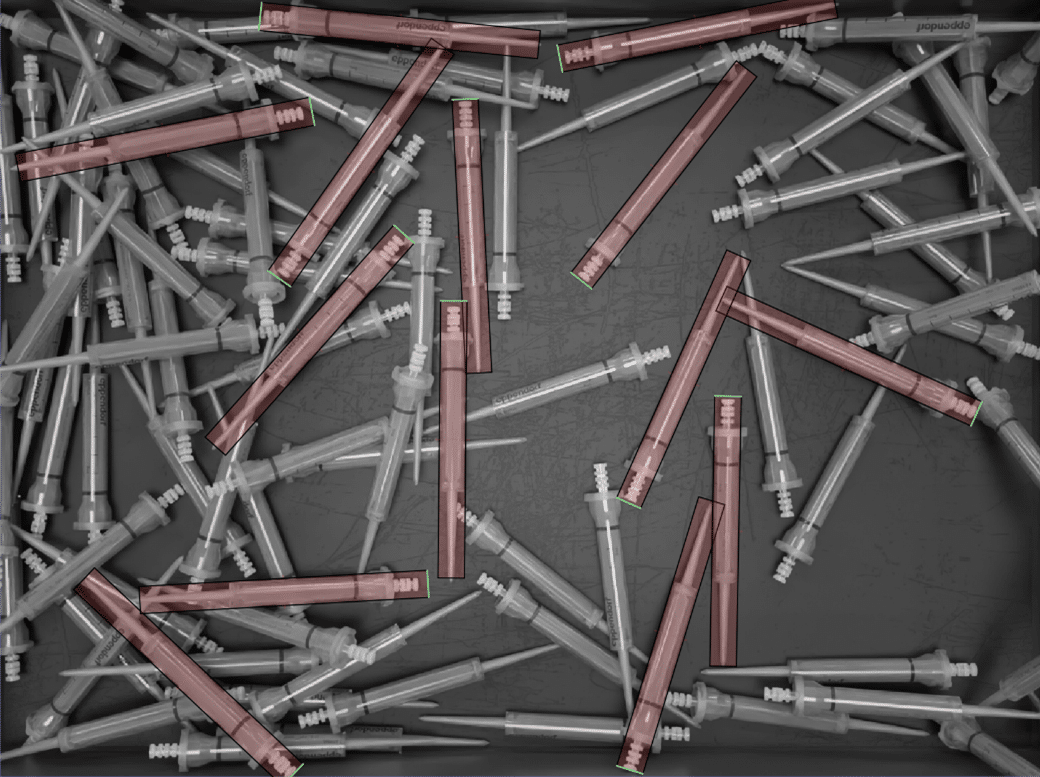

Oriented object detection enhances traditional object detection by not only identifying objects but also determining their orientation—specifically, detecting the direction in which the “top” of an object is pointing. Integrating orientation detection within the object detection process is more efficient than performing it as a separate step, reducing computational overhead and improving real-time processing. However, this combined approach presents challenges, as the concept of “top” varies by object type, requiring additional customization. This complexity limits the reuse of general-purpose models for oriented detection tasks.

Figure 1: Bin-Picking Scene of Syringes. The model detects only unobstructed Syringes. Their orientation is indicated by the green bar at their top.

To address this, Machine Learning Specialist Quirinus Schwarzenböck and his team at HD Vision Systems have developed a general approach that extends orientation detection capabilities to a broad range of existing models. This innovation allows for more precise and effective object interaction, particularly in bin-picking tasks, where accurate knowledge of both position and orientation of an object enhances robotic grasping and manipulation.

Deployment to Applications

HD Vision Systems provides a comprehensive pipeline to create custom, state-of-the-art object detection models for various purposes, including visual quality inspection. The LumiScan Annotation Framework enables the creation of custom object detection datasets. LumiScan Training transforms these datasets into high-performing (oriented) object detection models that integrate seamlessly into our applications:

LumiScan VGR: A solution for 3D bin-picking and quality inspection tasks.

LumiScan AI Object Matching: The 2D object detection application within the CtrlX ecosystem, an edge computing platform for PLC based applications.

Custom Software: Tailored solutions for specialized industrial needs.

As technology continues to advance, object detection will further revolutionize industrial automation, driving the development of adaptive, precise, and robust systems that enhance both productivity and quality. I, Quirinus Schwarzenböck, am excited to explore this future as a machine learning expert, continuously pushing the boundaries of innovation and delivering cutting-edge solutions to industrial vision challenges.