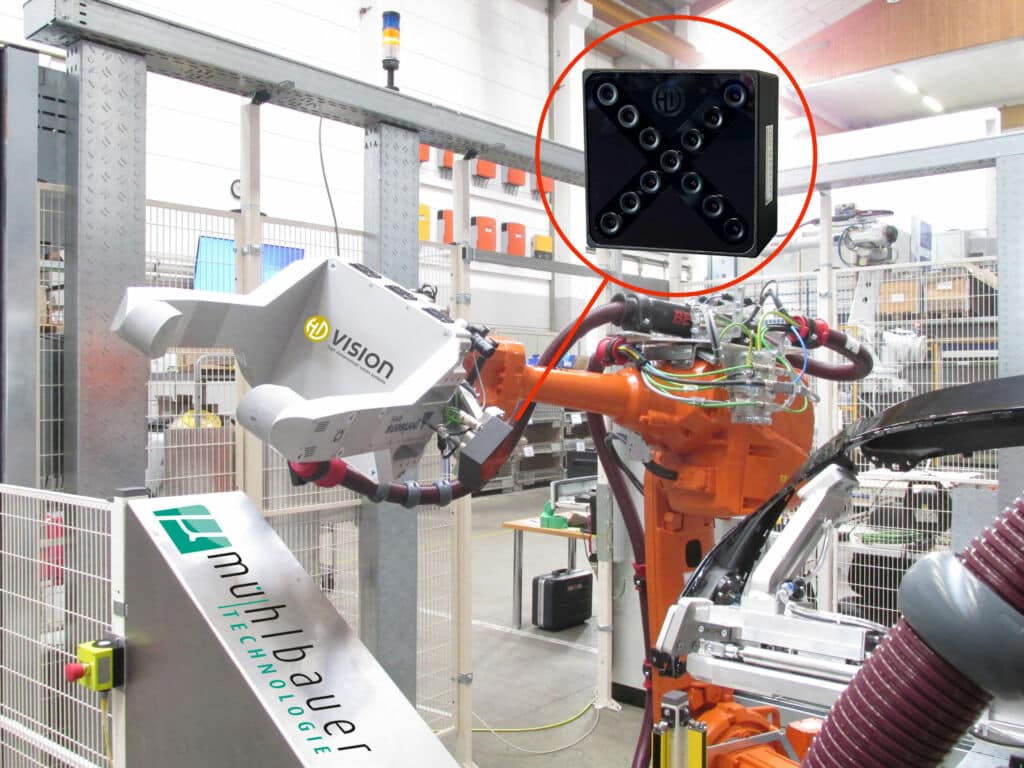

With the LumiScan VGR Vision Guided Robotics software, HD Vision Systems makes it feasible to combine state-of-the-art image processing applications and analysis methods with robot motion control. The practical application of an inspection system for front and rear bumpers by Mühlbauer Technologie demonstrates this concept. This system, which incorporates LumiScanX light field cameras and the optimized vision guided robotics software LumiScan VGR, exemplifies how it works in real-world scenarios.

One of the robot programmers at Mühlbauer Technologie defines the task as follows: “Our requirement was a simple, intuitive and clear software solution that runs outside the standard bin picking application. This was the first time we were dealing with an inspection system for front and rear bumpers. Currently, the camera system and software are primarily used for production and radar capability testing of exterior automotive components. To meet the requirements, HD Vision Systems customized the standard version of the LumiScan VGR with two LumiScanX light field systems and two LumiScan Spot pattern projection units. The complete system uses light field technology that effectively reduces reflections, glare and occlusion, resulting in significantly better and higher quality point clouds on the glossy painted bumpers. This makes it possible, for example, to identify the component type and determine its exact position in space, as well as to detect any deformation of the flexible components.

Robot path & camera position

The light field technology of the Lumiscan X reduces reflections, glare and occlusion, resulting in significantly better point clouds on the painted bumpers.

The robot interface required for this application was developed in collaboration between the developers at HD Vision Systems and the programmers at Mühlbauer Technologie. The robot’s path is corrected to reach all relevant inspection points on the direct surface of the part. This ensures that even twisted parts are measured at the correct point. All of these calculations – including robot path determination – are performed by the software in fractions of a second.

One of the most important decisions was the camera position. In the first concept, two camera systems were mounted in a fixed position, which had advantages in terms of cycle time, but limited flexibility with regard to component variance. In the current concepts, the LumiScanX systems are mainly guided by the inspection robot to achieve maximum area coverage and flexibility. Since the images are always taken from the painted surface, the images are highly dependent on the exposure setting of the camera. The systems are therefore designed as enclosed booths to provide constant lighting conditions regardless of the time of day or hall lighting. Highly reflective and dark component types were the most difficult to detect. The solution was to merge multiple images. To improve the performance of the 3D light field cameras, each camera was supported by LumiScan Spot pattern projectors. All the collected data has been processed in LumiScan VGR, whose main task, in addition to precise component measurement, is to check whether the generated robot path is within the safe range and completely collision-free. Depending on the result, the path coordinates are recalculated.

Adapting to new components

Many customers have a wide variety of components and require easy integration of new components into their inspection systems. The HD Vision System solution allows the use of a simplified component support for many similar components, such as front or rear bumpers. The component support can be set to different parameters. This eliminates the need for additional, product-specific hardware for the integration of new components, as these can be taught in software only. Thanks to the direct connection to the robot as a ProfiNet slave and a specially adapted interface, HD Vision Systems has created a system solution that is already being used successfully in thirteen test systems in Germany and internationally.

About Mühlbauer Technologie GmbH

The core competences of Mühlbauer Technologie GmbH and its 12 employees is automation and special machine construction.

In addition to the automotive and automotive supply industry, small and large electronics, medical and aerospace companies from all over Europe form part of a broad customer portfolio. Mühlbauer Technologie GmbH speak the languages of their customers and are always able to meet national and international challenges.